ALFA

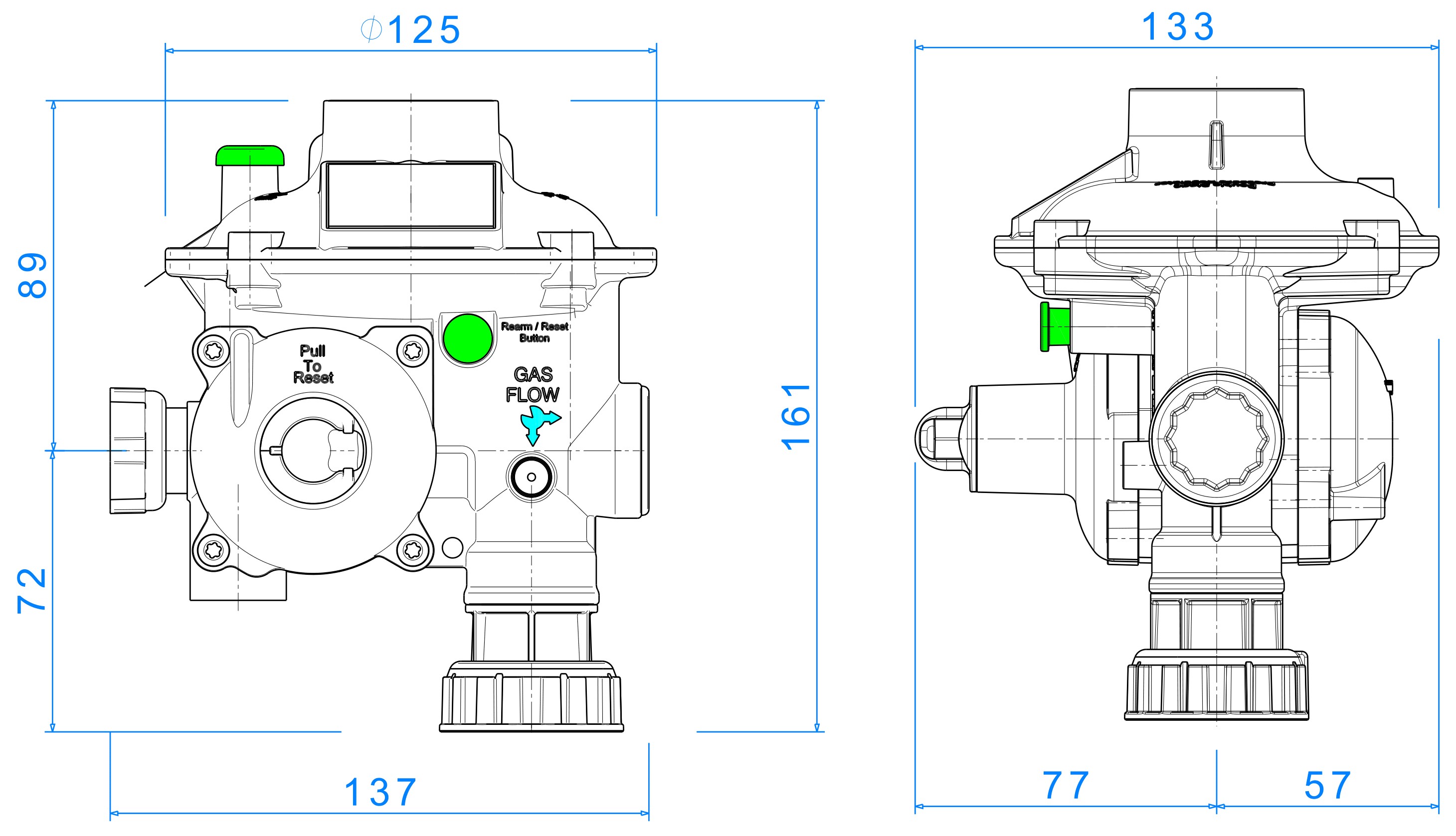

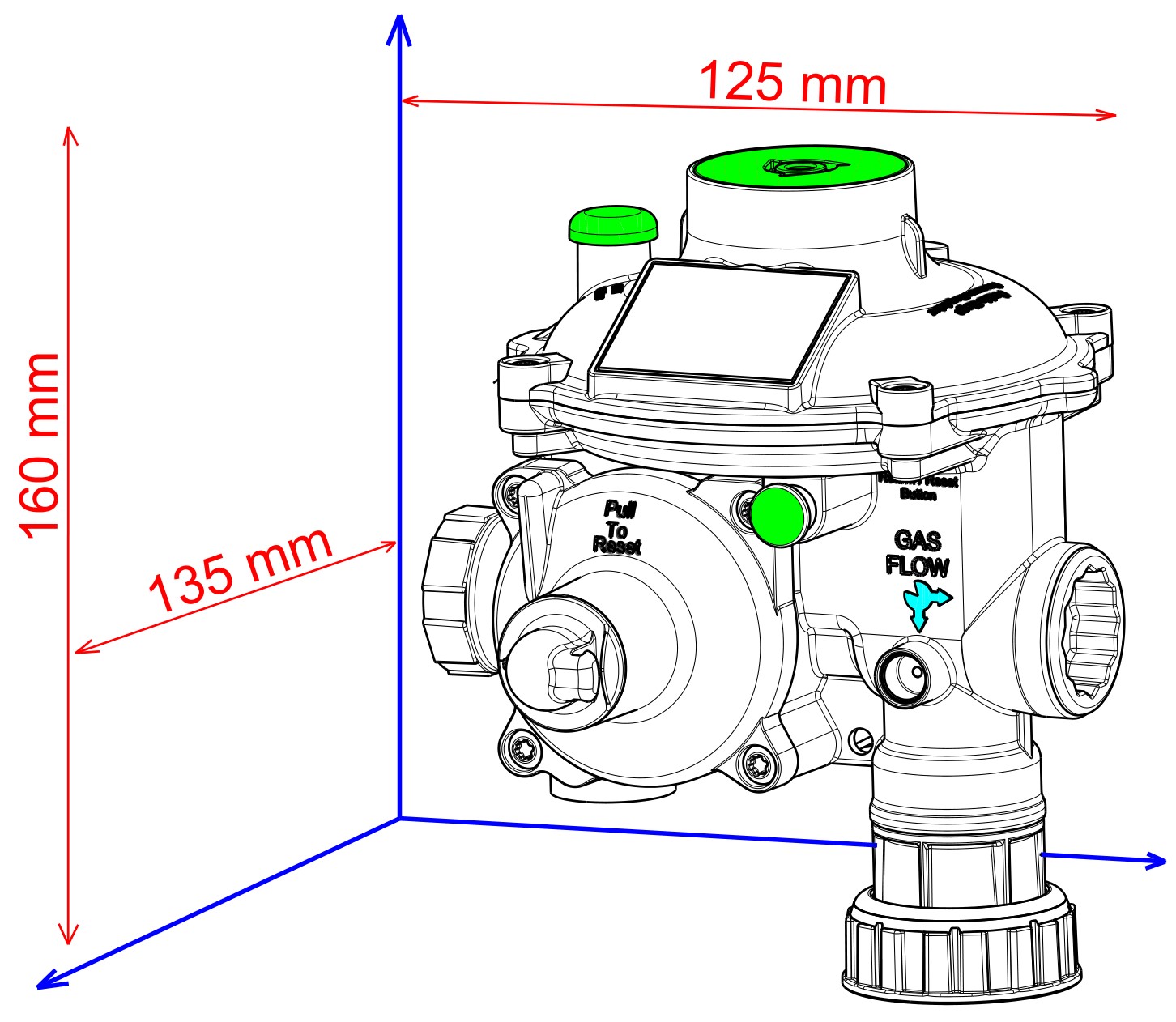

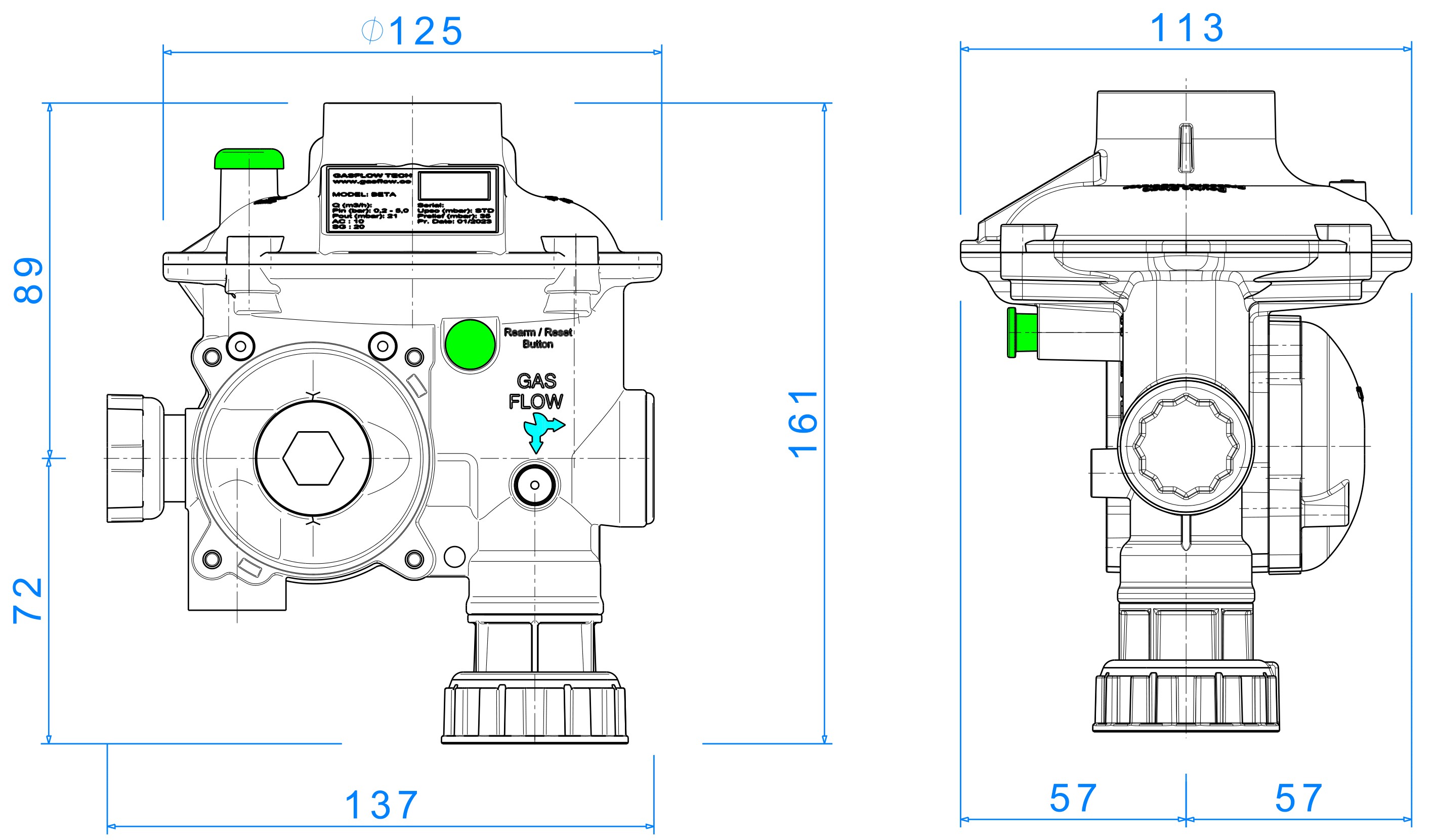

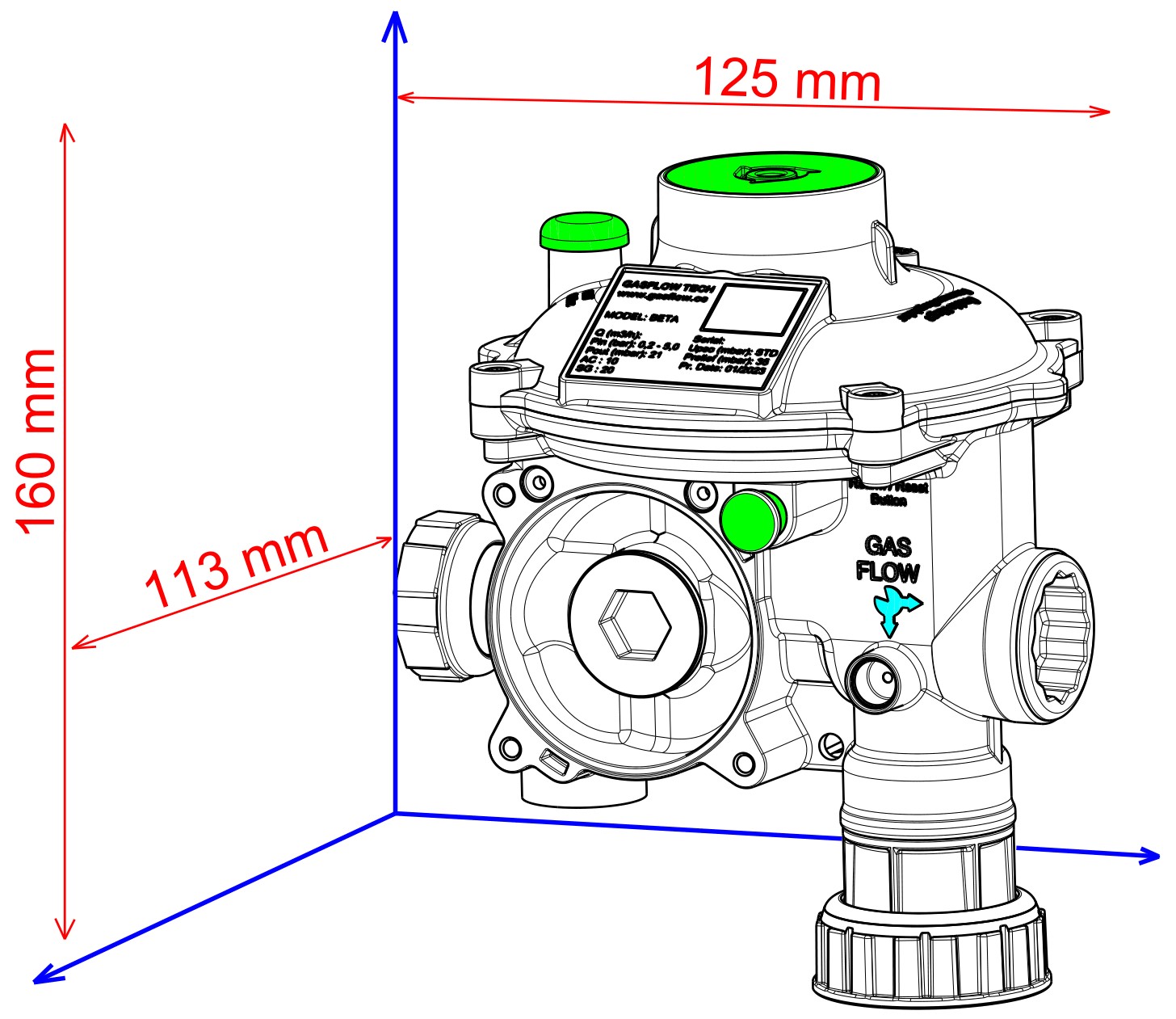

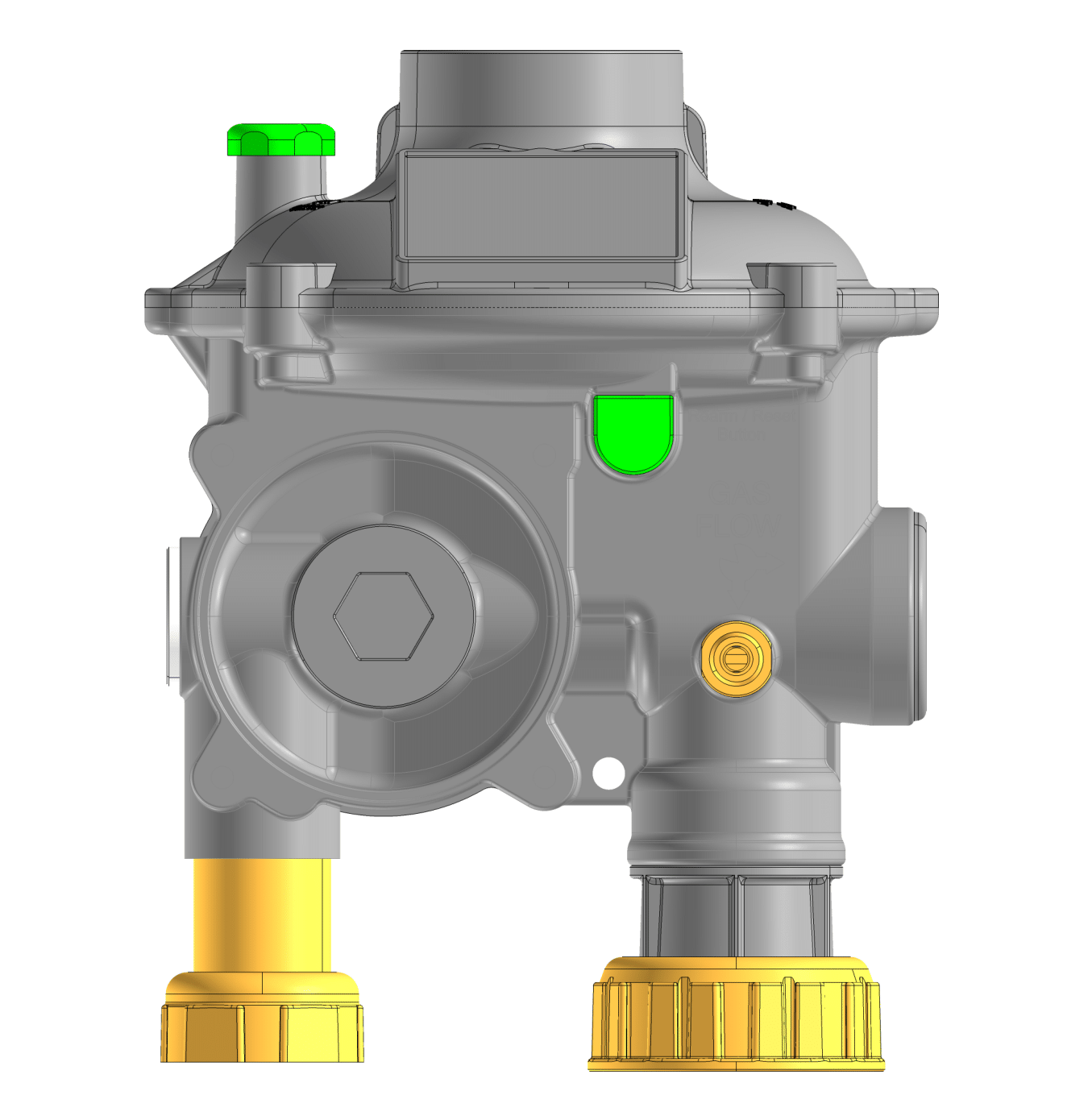

ALFA - Series (2.5m3/h→ 50m3/h)can be used at outlet pressure between 9→500 mbarby configuring properly of the regulator bill of materials.

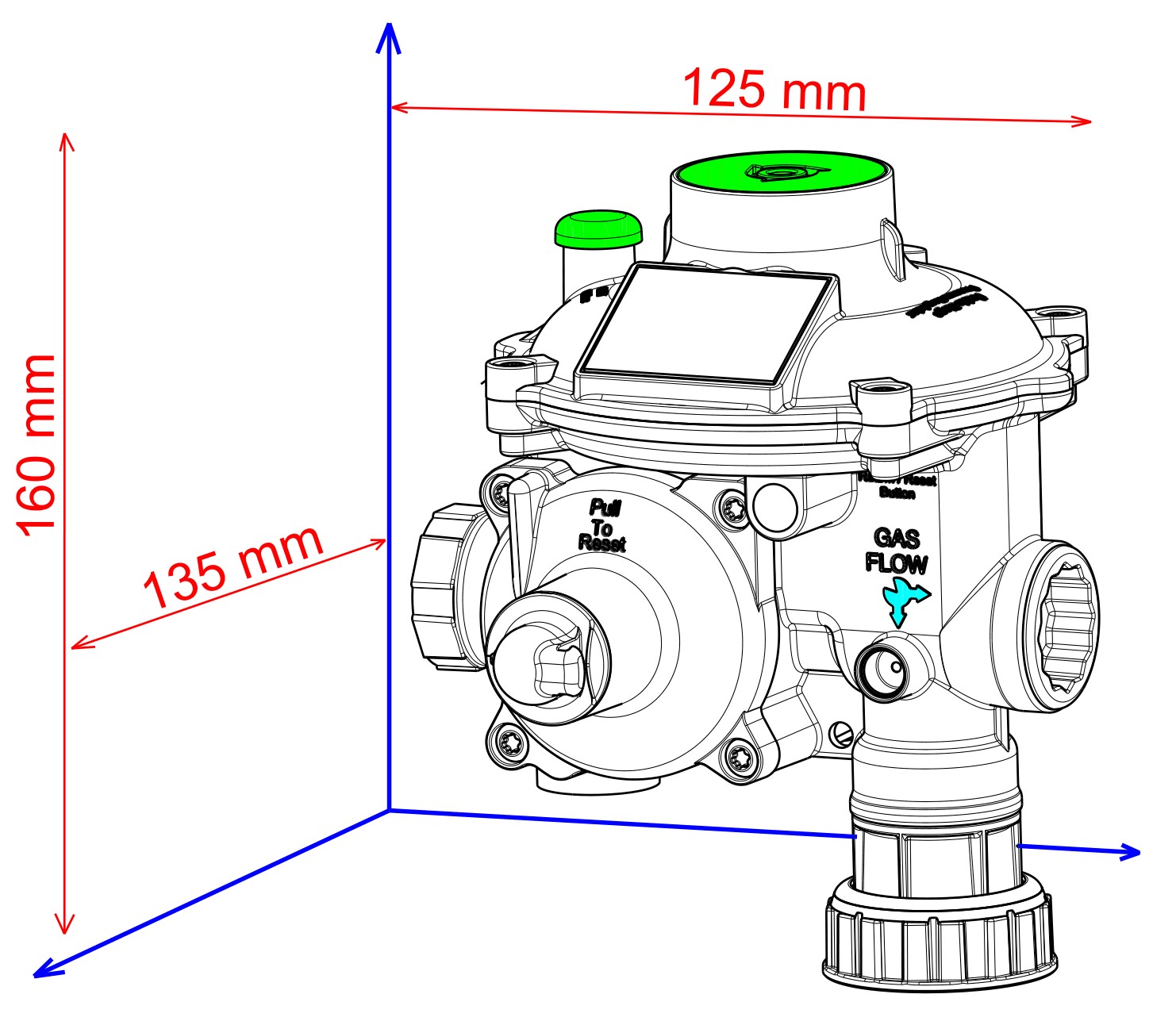

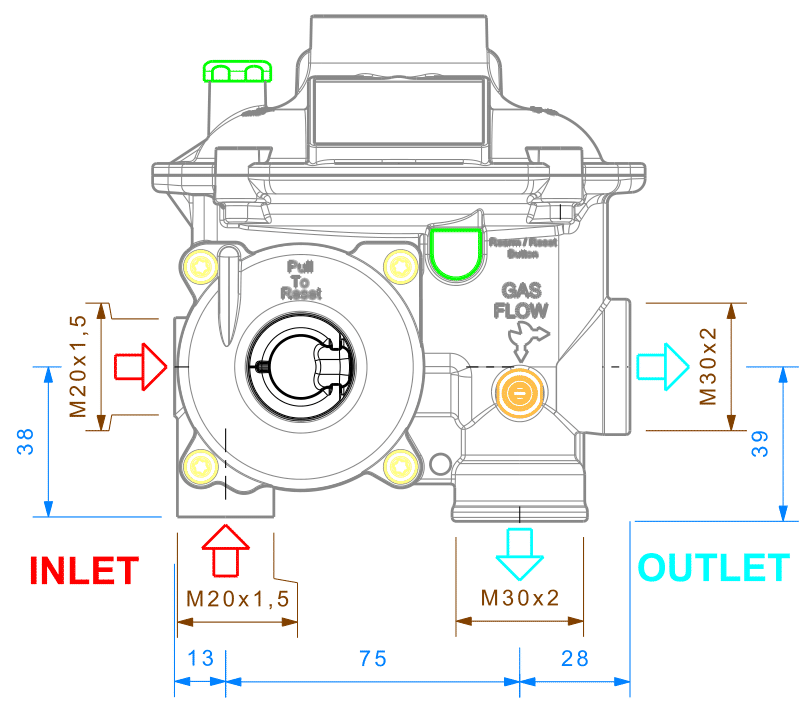

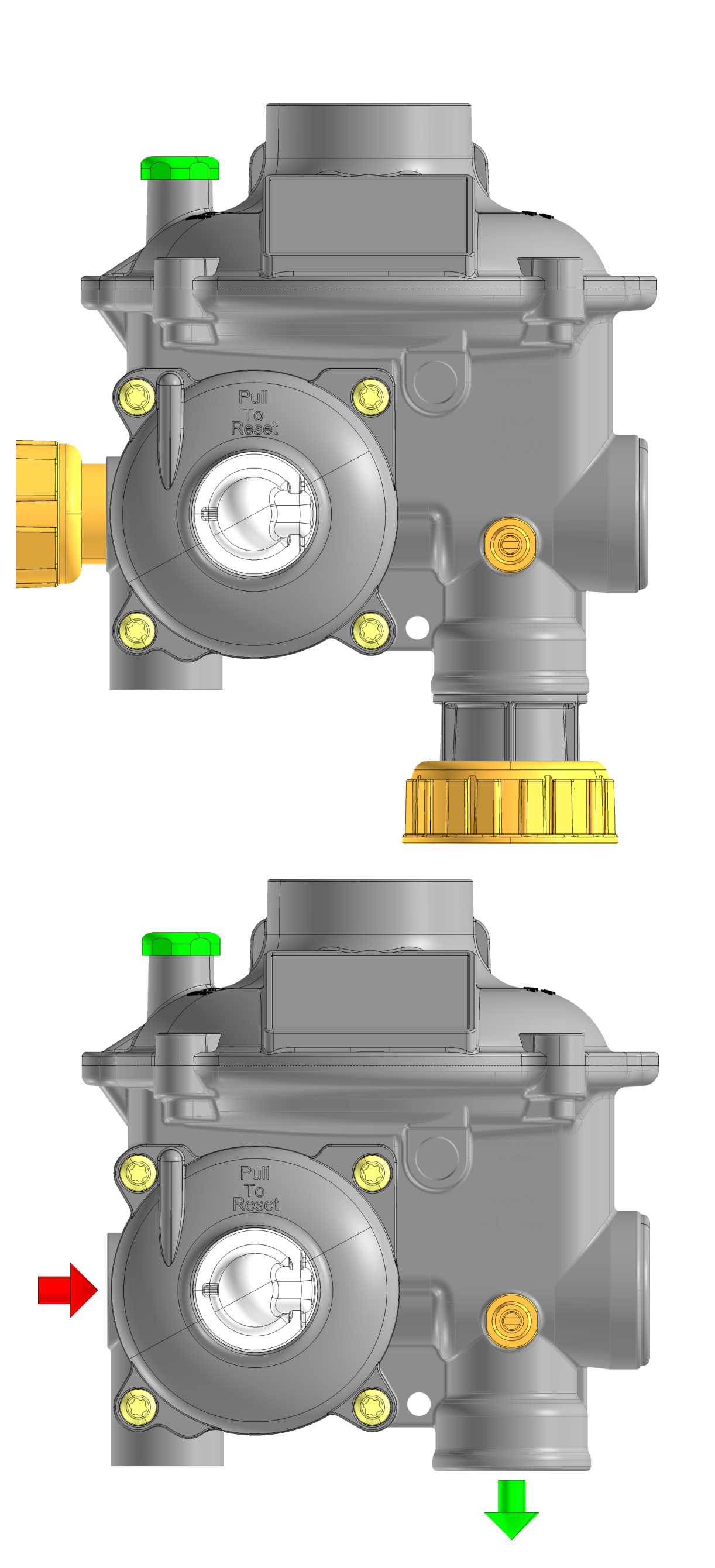

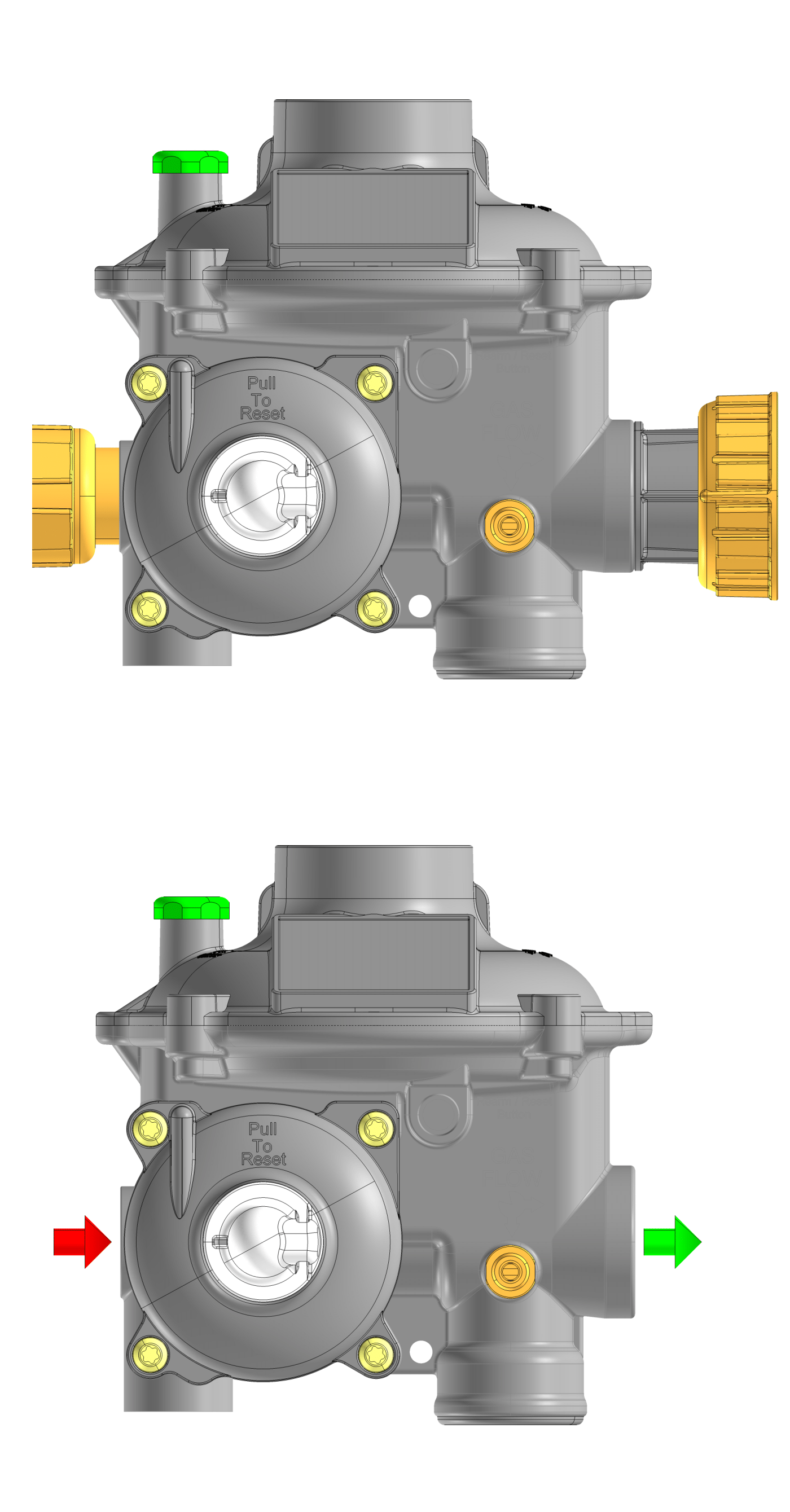

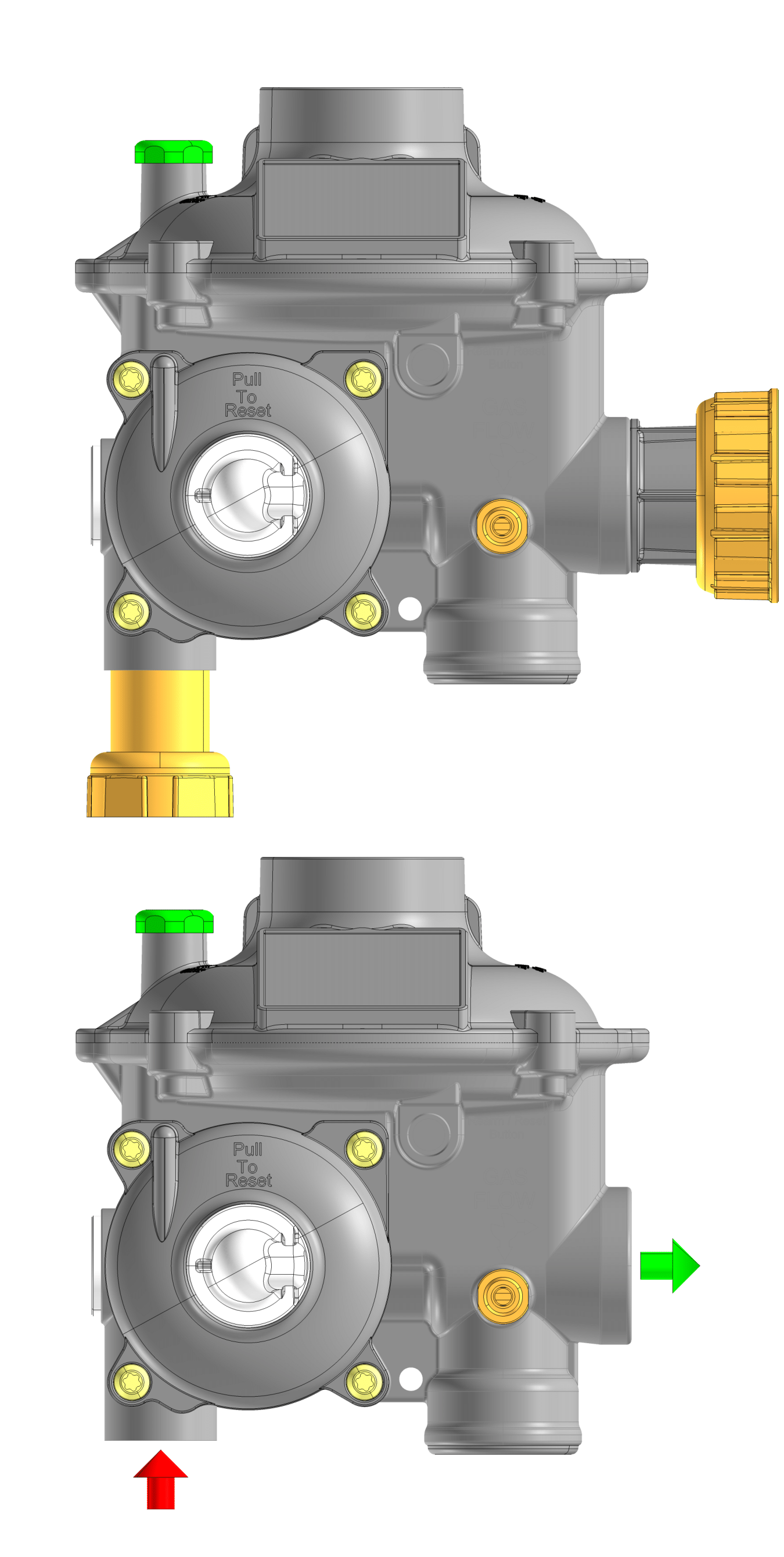

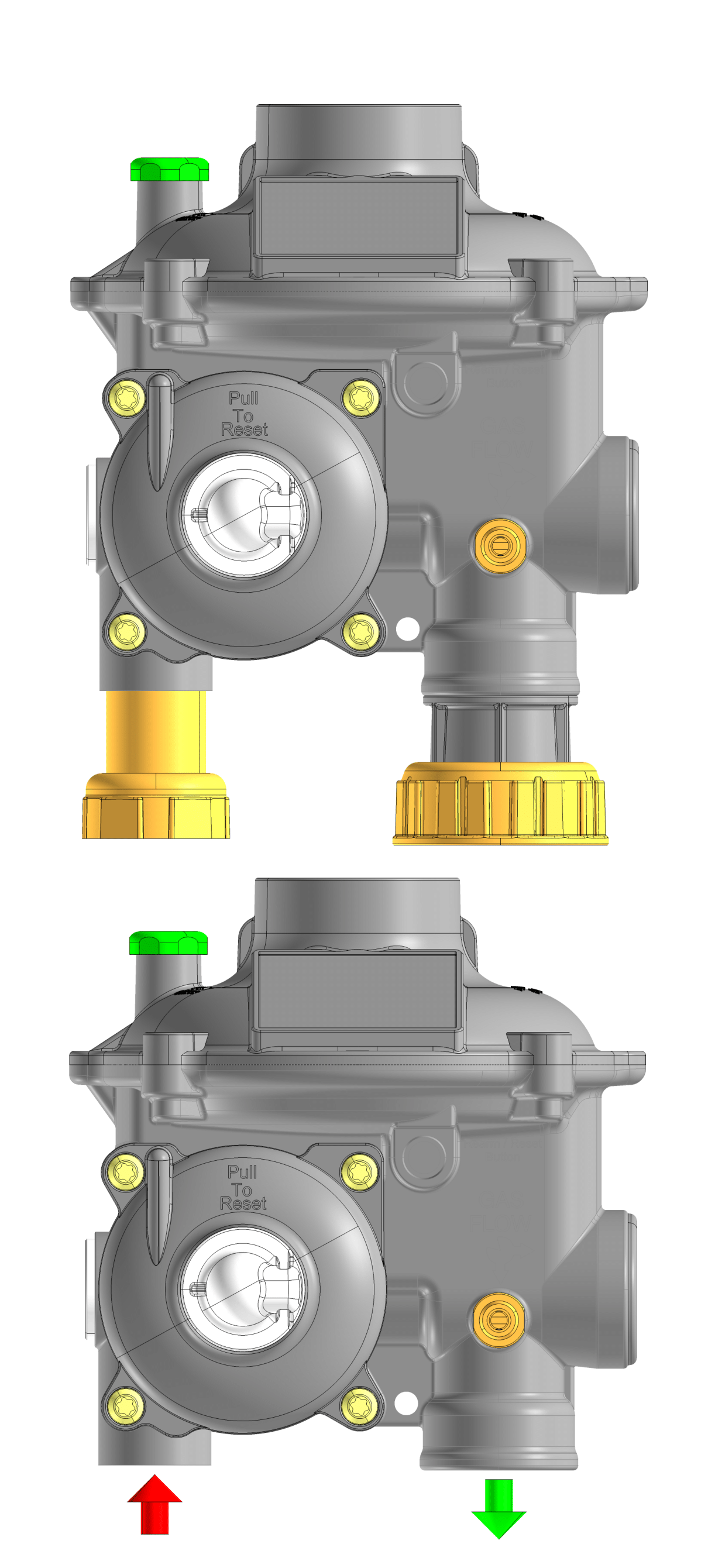

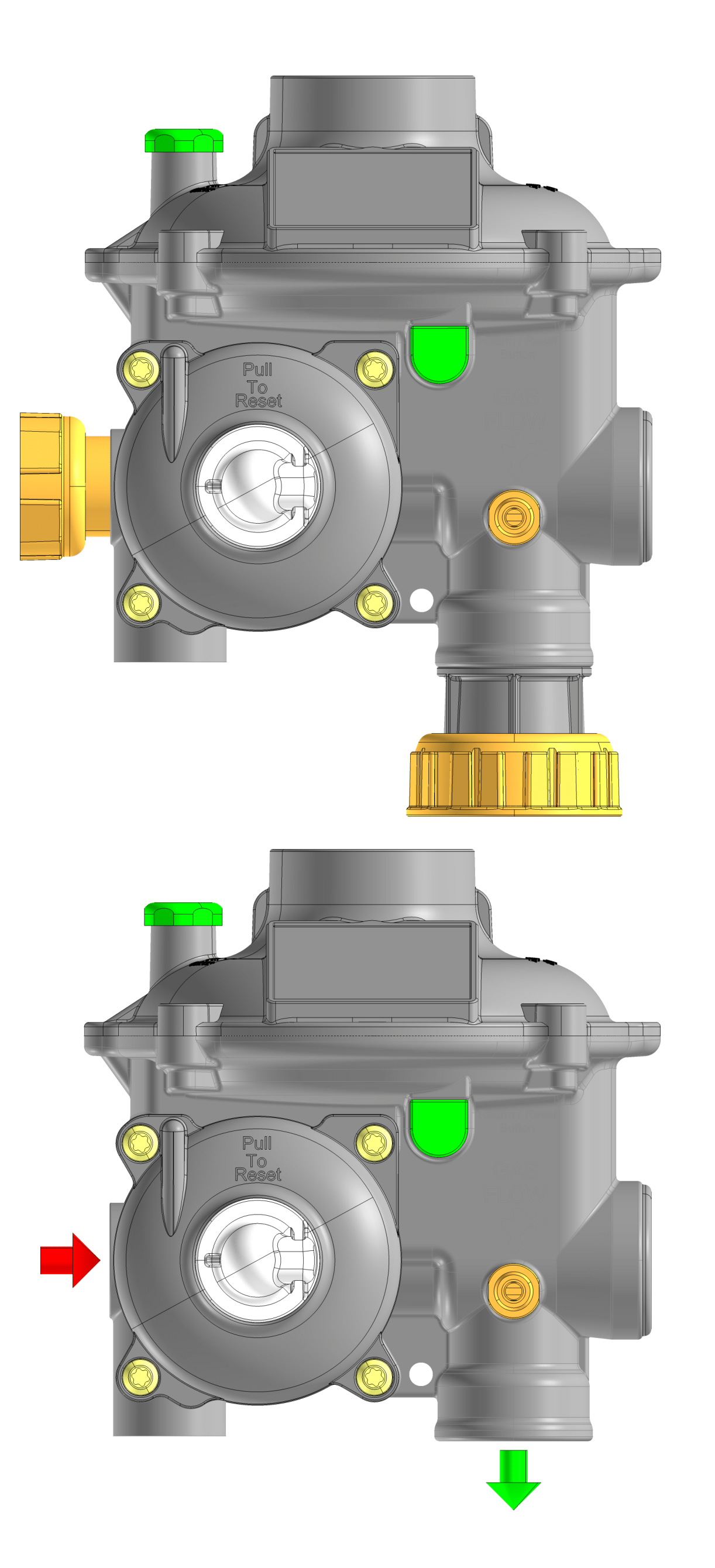

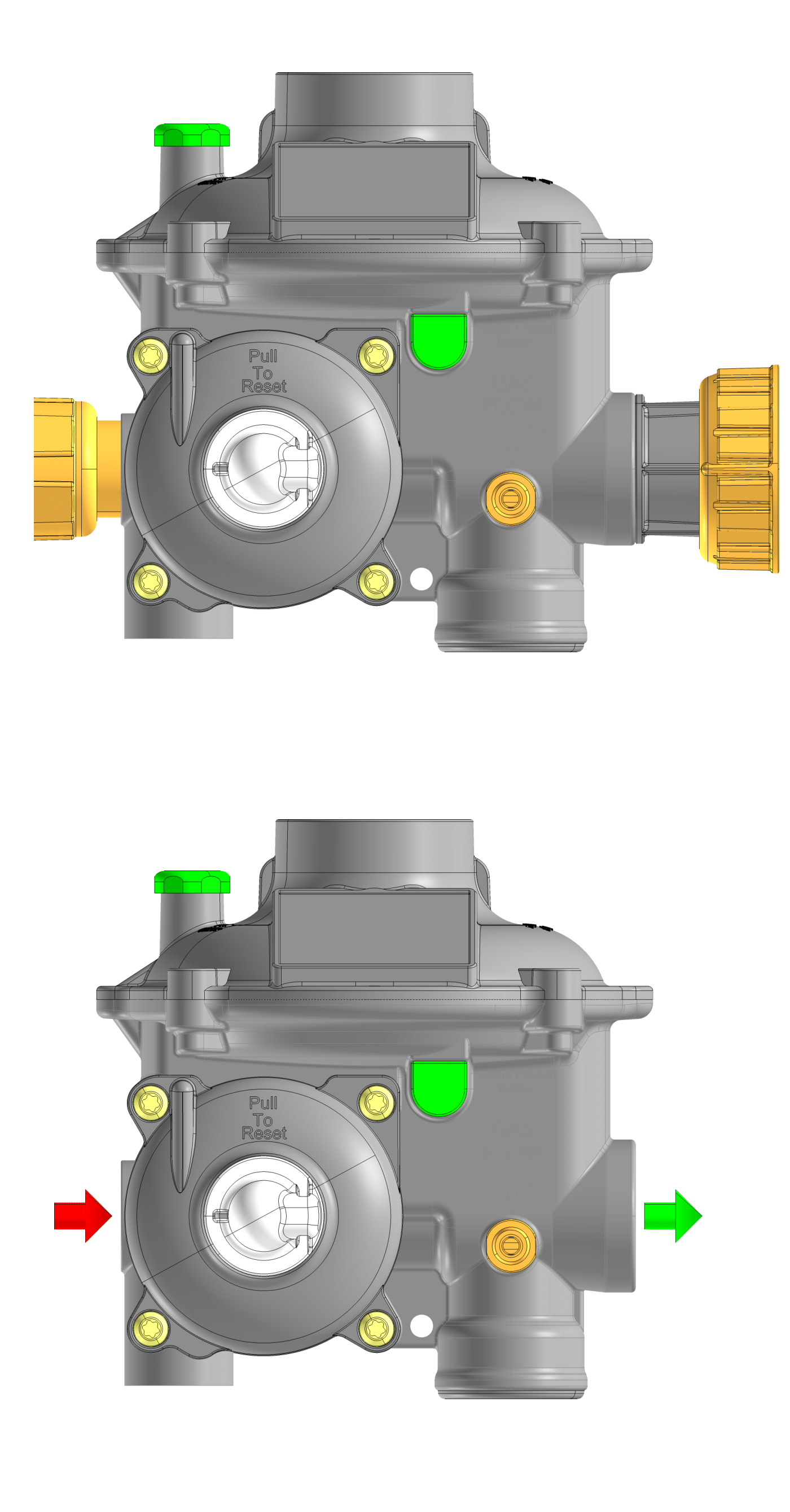

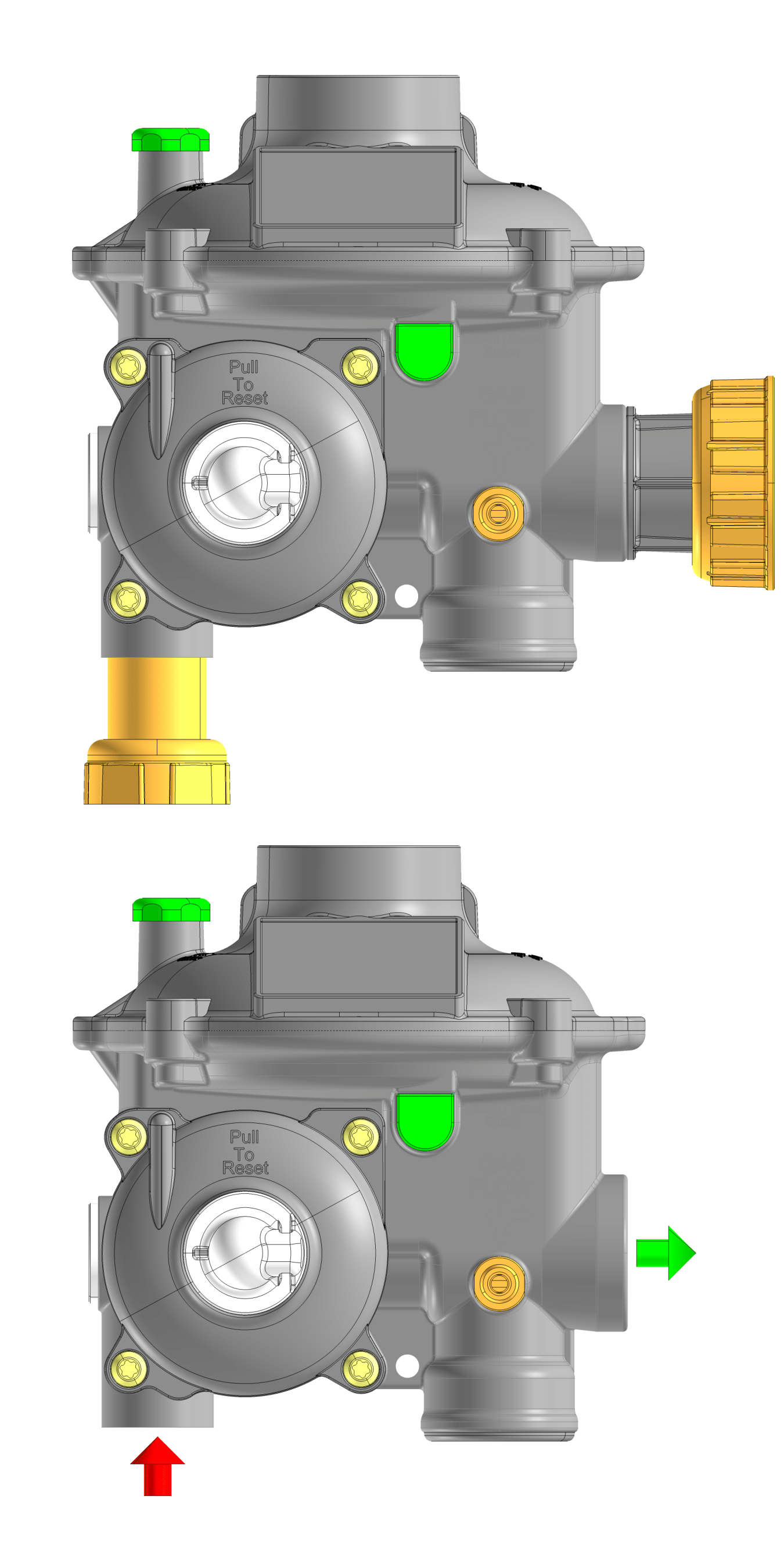

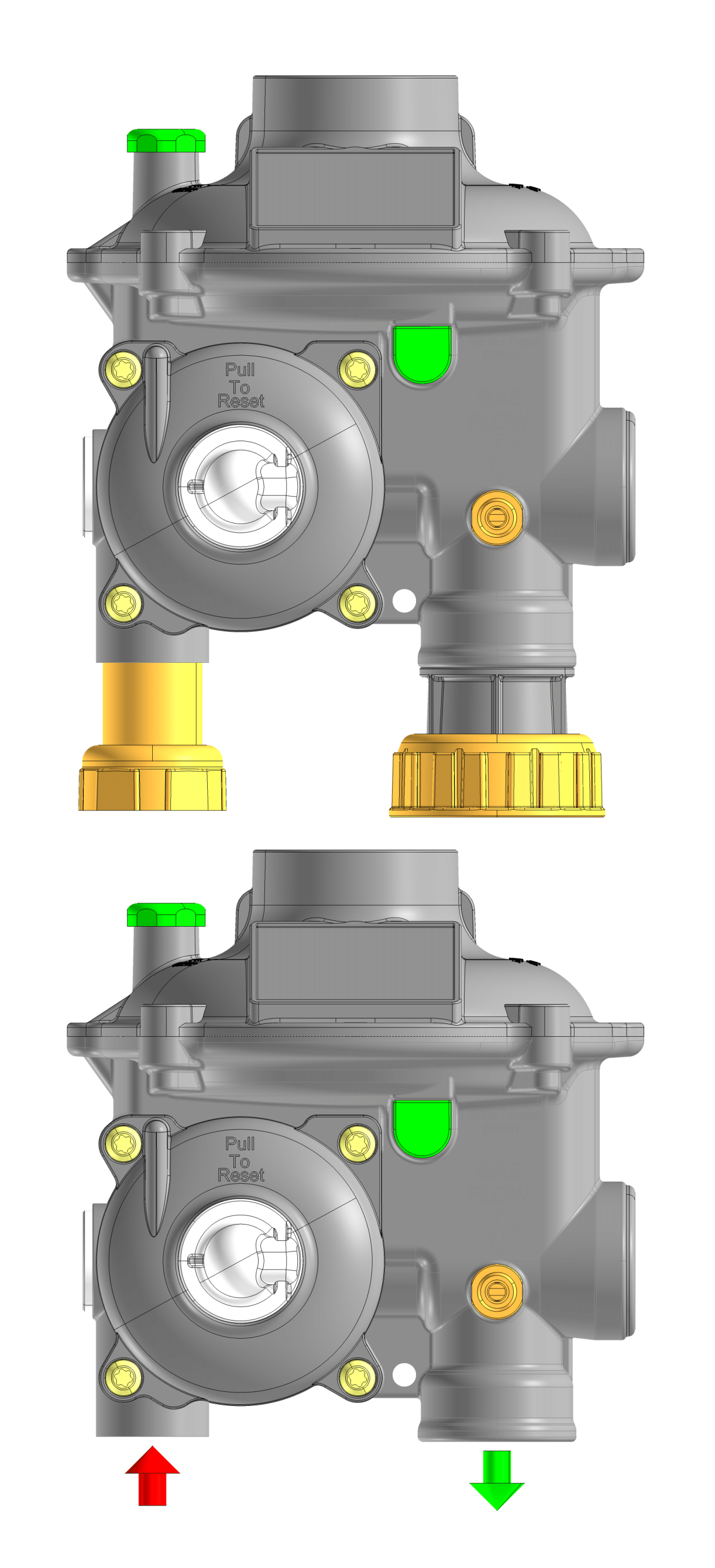

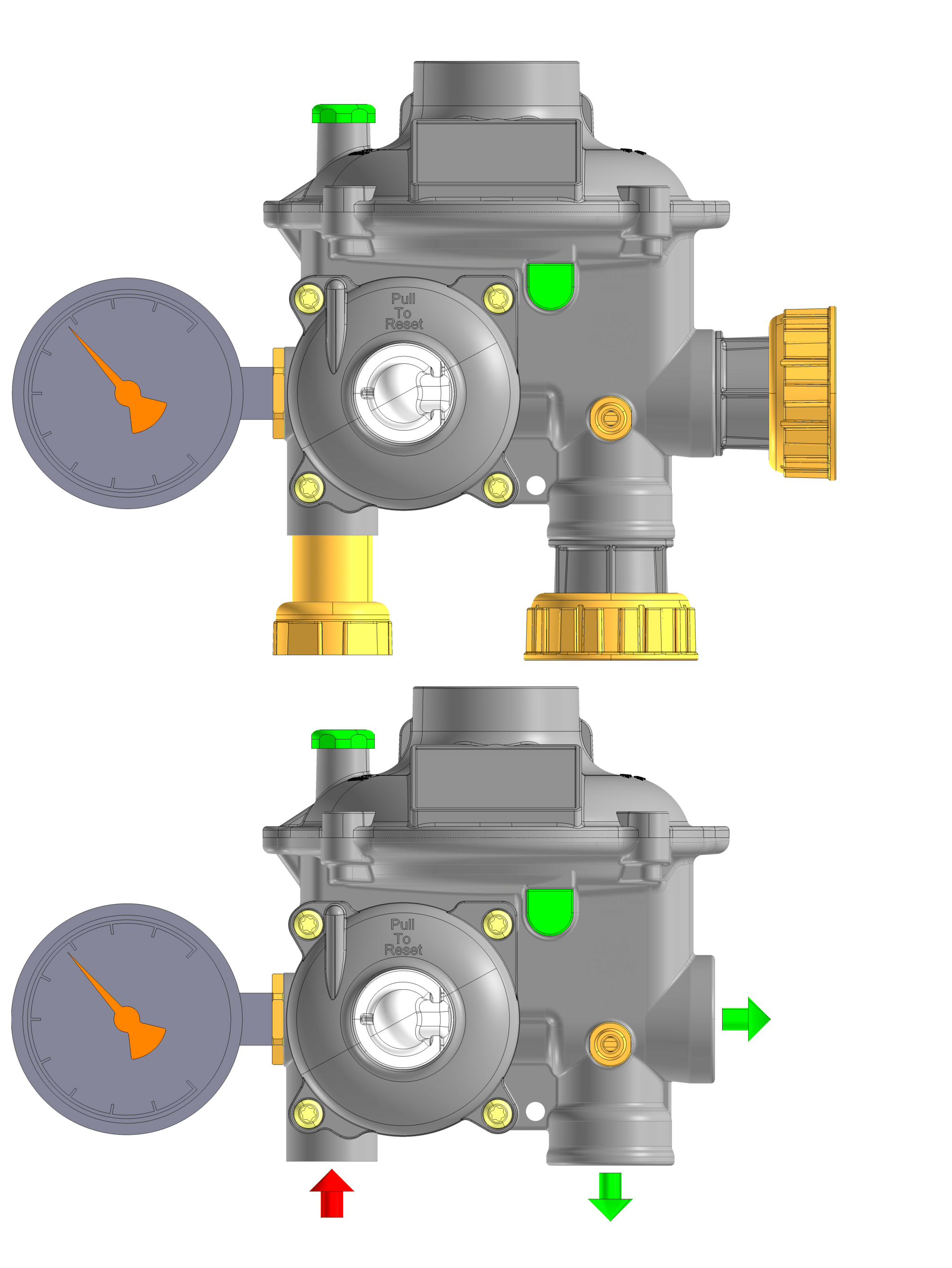

ALFA - Series regulators are designed to be installed outdoor/indoor , wall mounted/underground box with different inlet/outlet configurations (Angle, Inline, U, T, Q), in individual domestic gas systems and meters

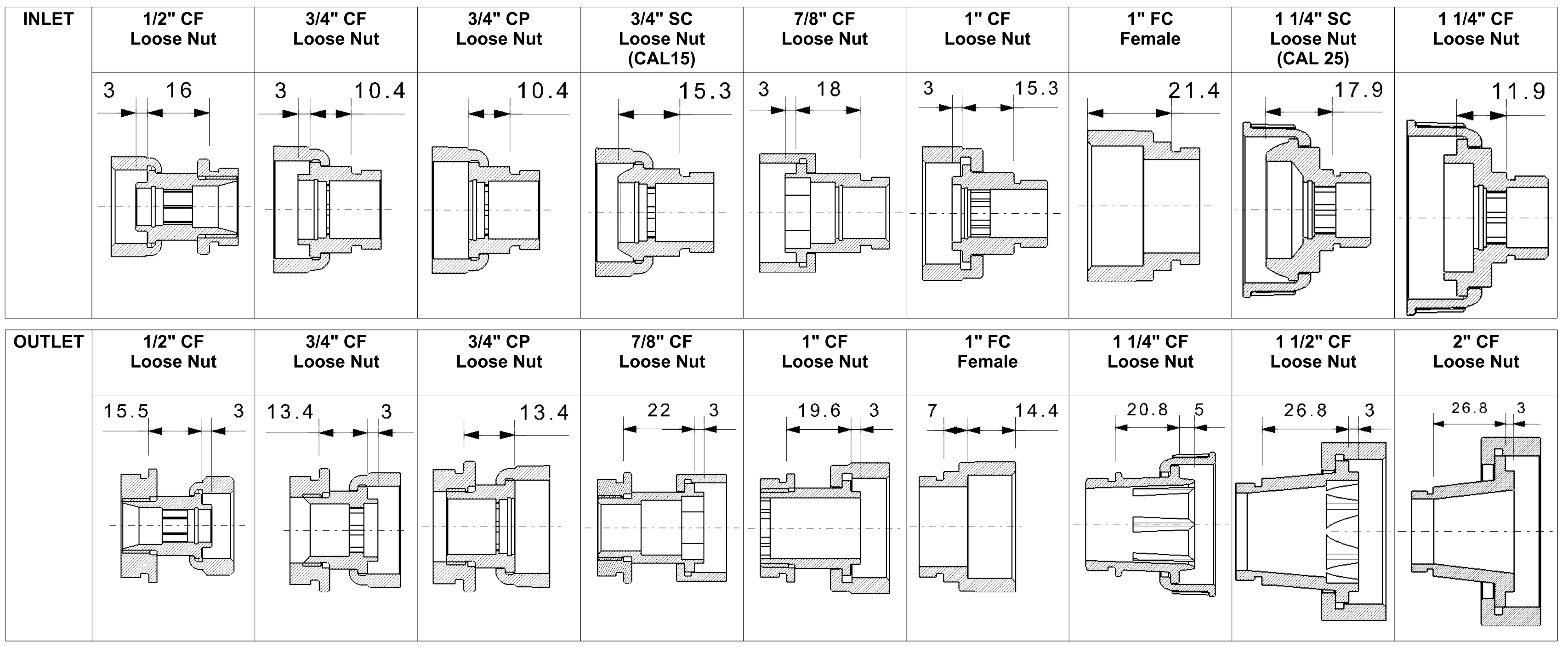

Inlet and outlet connections can be customized according to customer needs and standarts.

Thanks to smart engineering to achievie high reliablity and accuracy in regulation yielding measurement correction errors to keep at minimum level.

All service regulators are produced according to the international norms and standards such as EN88-2 and TS 10624.

GENERAL

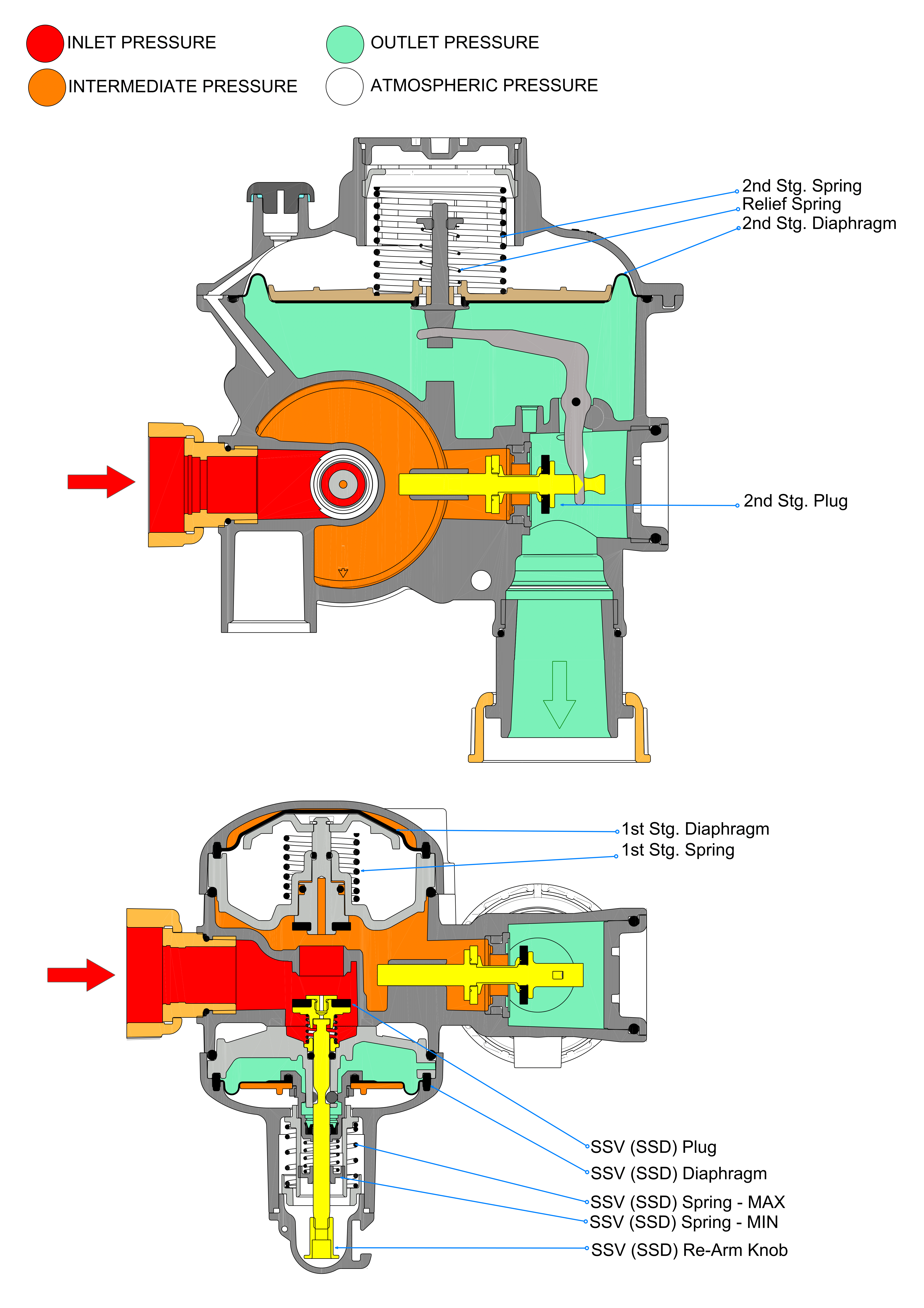

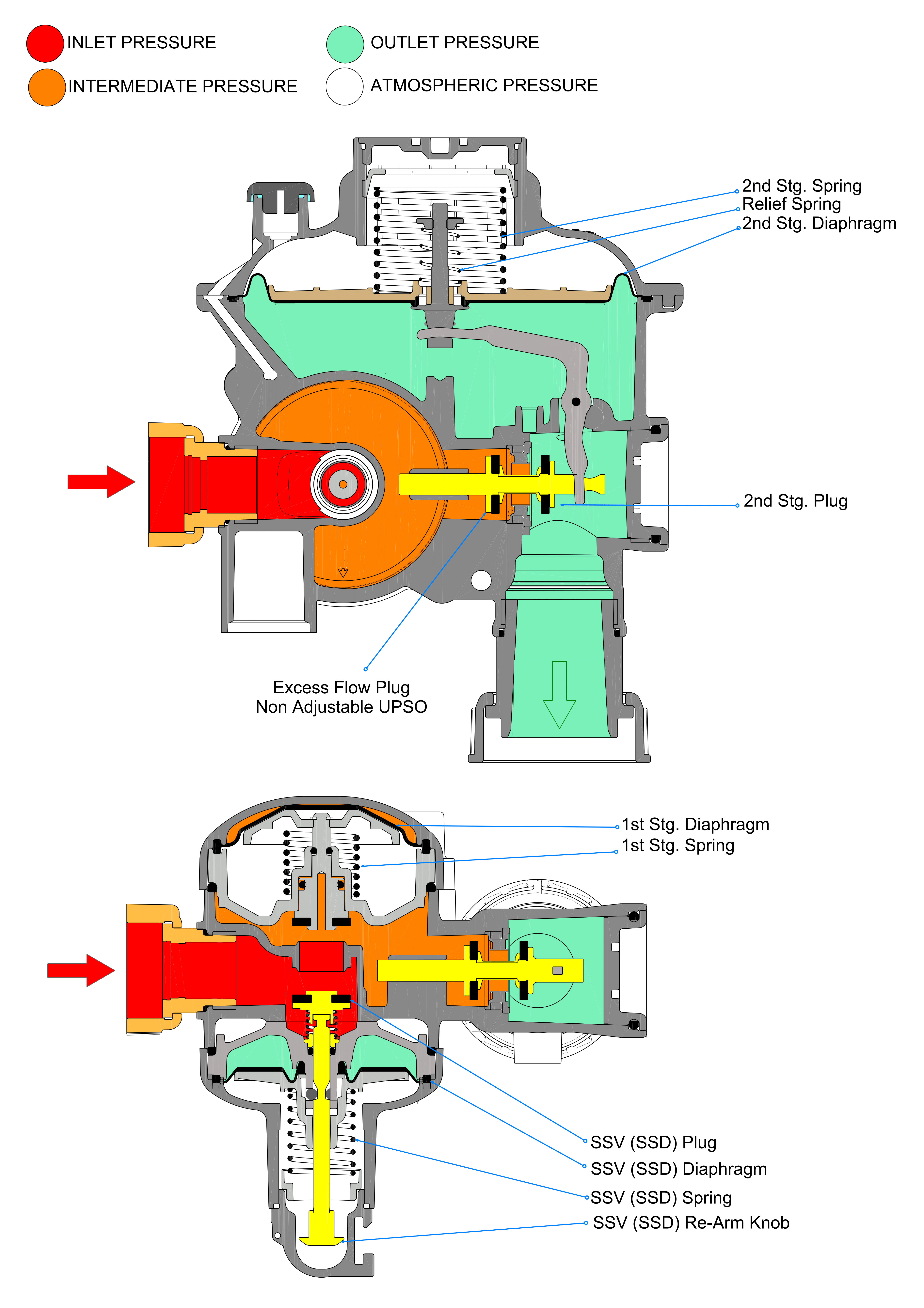

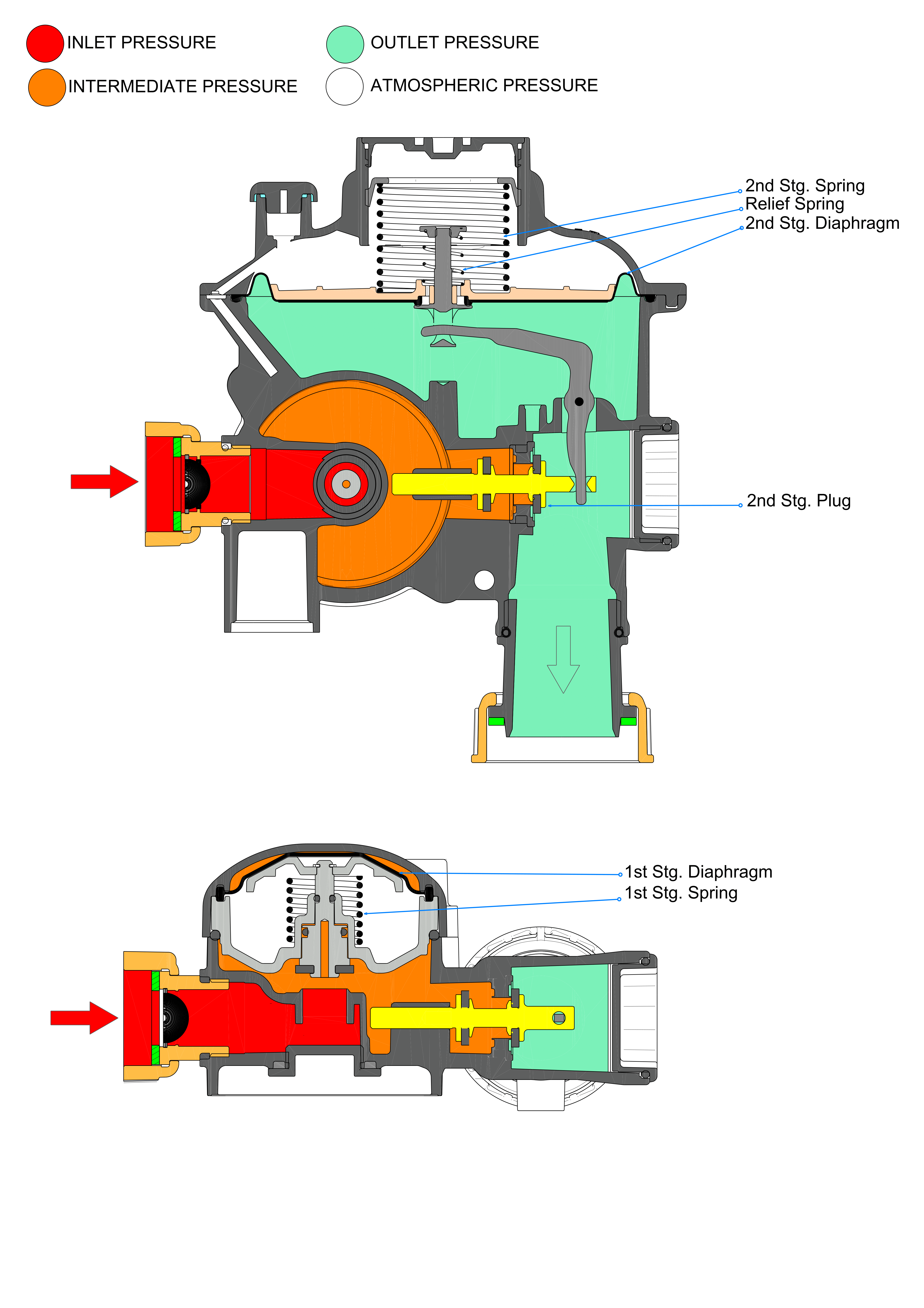

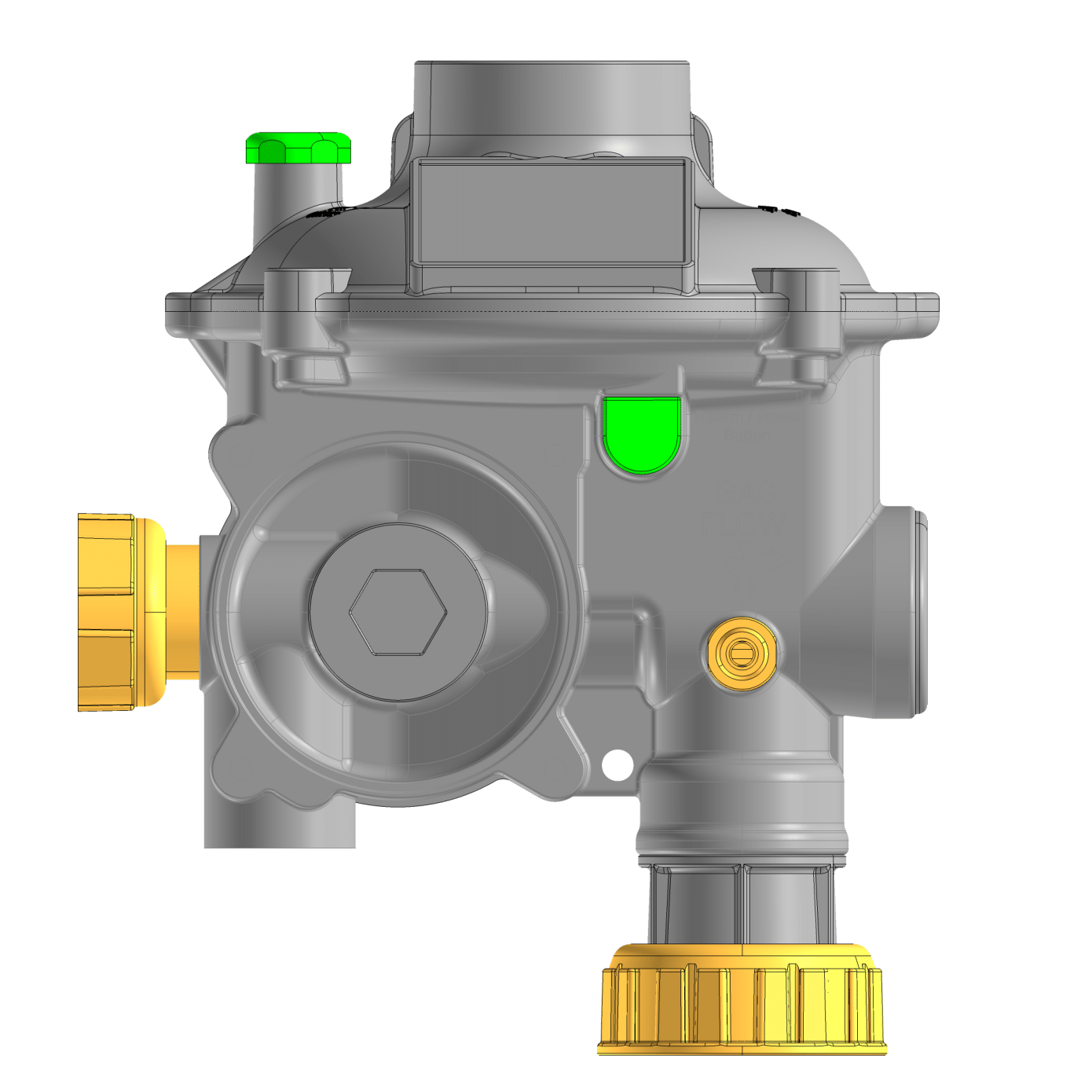

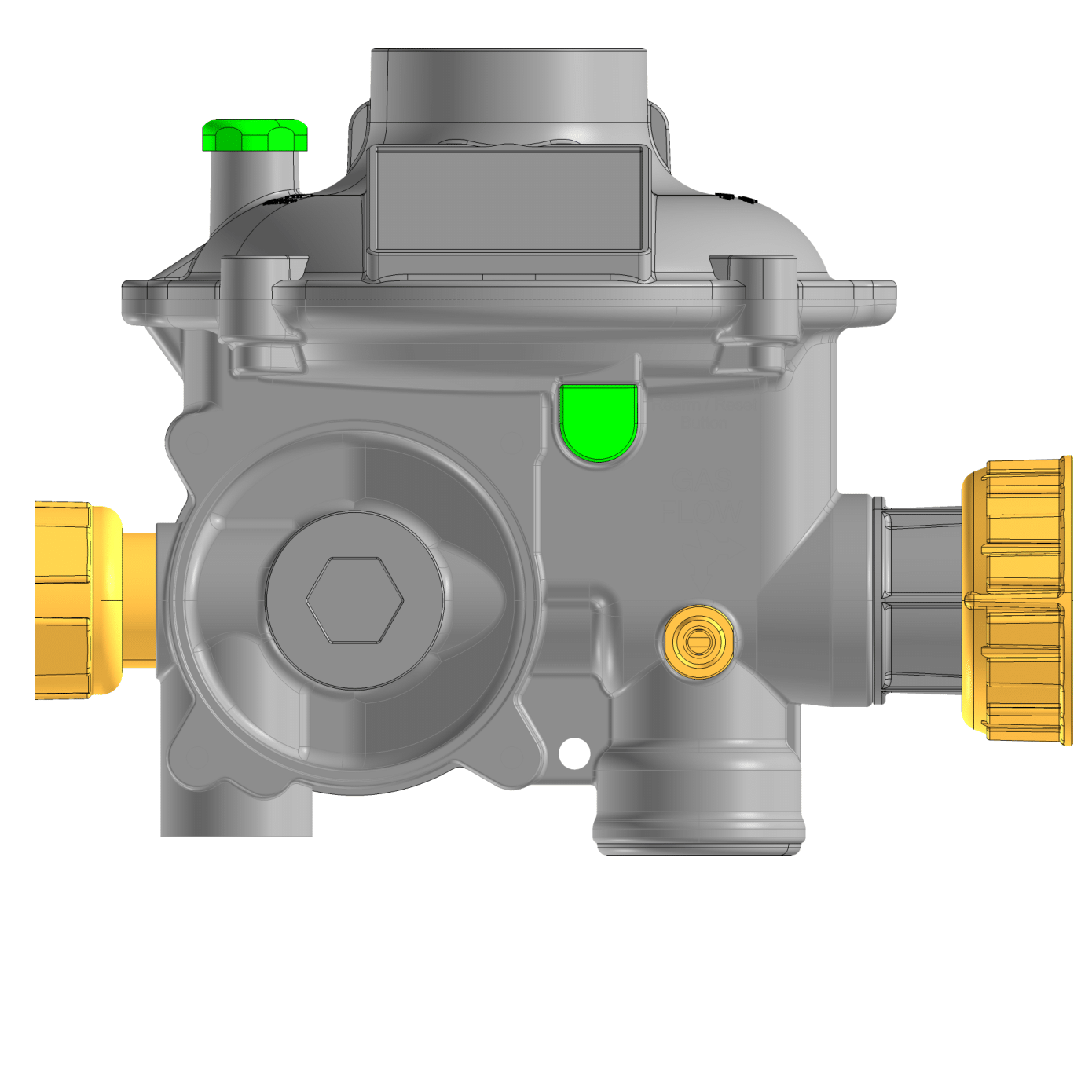

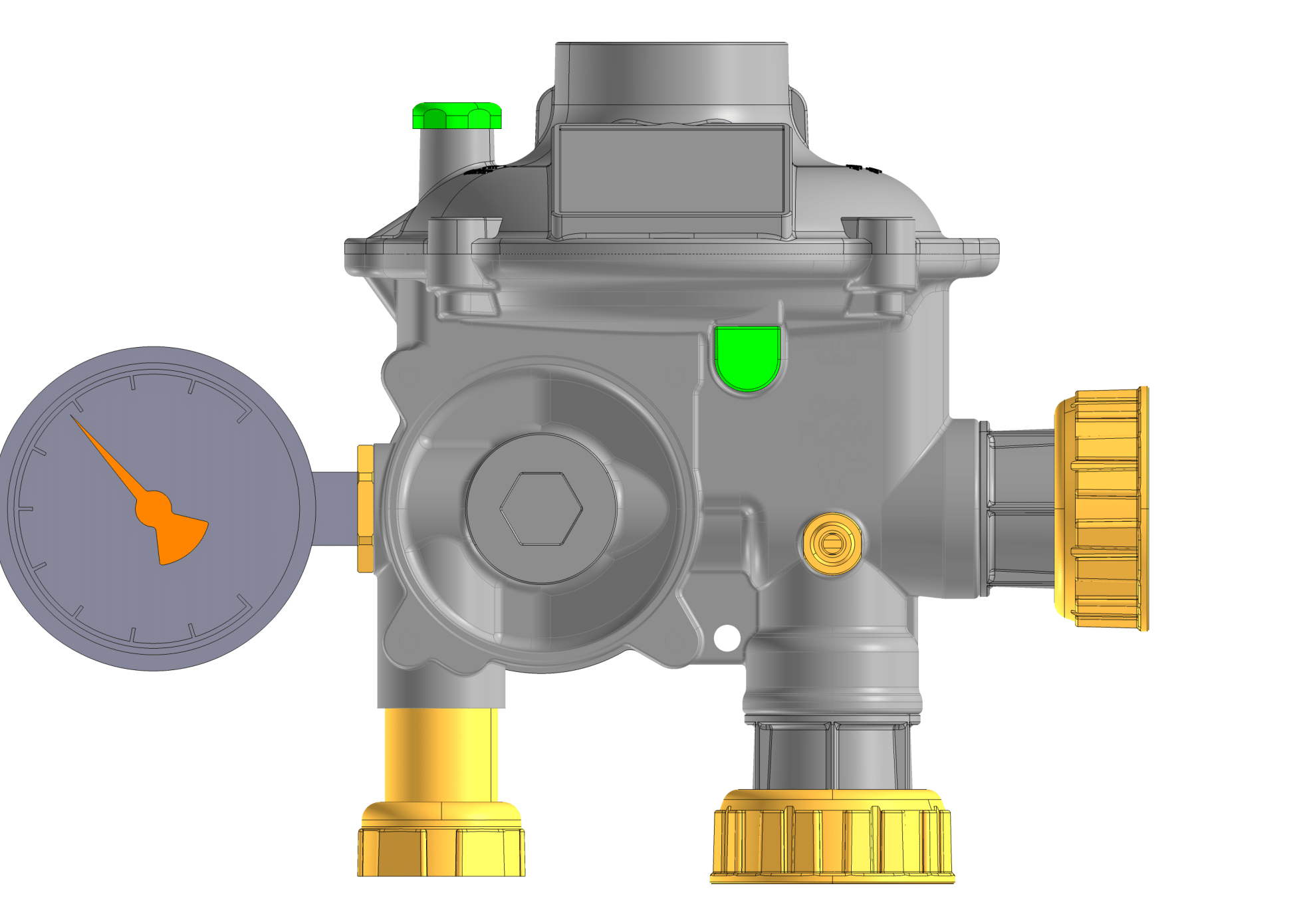

The primary function of a spring loaded two stage gas regulator is to

match the flow of gas through the regulator to the demand for gas

placed upon the system. At the same time, the regulator must maintain the system

pressure

within certain acceptable limits.

Since the regulator’s job is to modulate the flow of gas into the system,

restricting

element (1stand 2nd stage plug) that will fit into the

flow stream is essential and needed to provide a variable restrictied

modulation of the flow of gas through the regulator.

In order to cause restricting element to vary, loading element

(1stStage , 2nd Stage, relief , Over Pressure Shut Off (OPSO )/ Under

Pressure Shut Off (UPSO) springs) is needed which can apply the

required force limits to the restricting element. And measuring element (1stand

2nd , Slam

Shut Valve (SSV) diaphragm)which tells

regulator when flow has been perfectly matched and characterized

to desired values is needed.

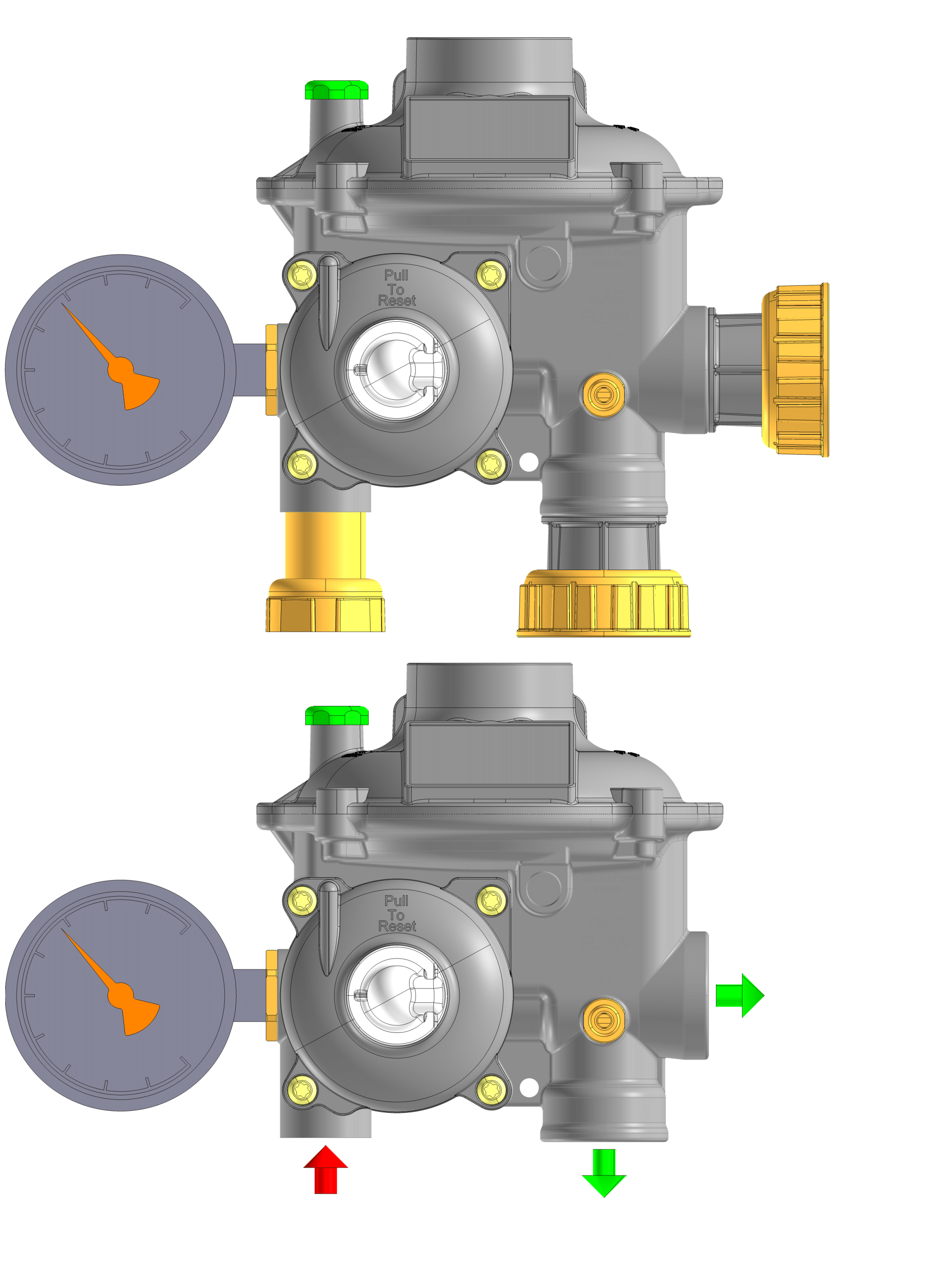

Outlet pressures over than set value is managed by built-in relief valve, OPSO valve, whereas below than outlet set value is managed by UPSO valve in SSV for secure operation. Built-in relief valve triggers when set value is reached to compansate outlet pressure increase such as termal expansion in downstream even apliances are off. OPSO/UPSO SSV is a safety device of which its restoration takes place manually prevents gas flow if anomalous downstream pressure conditions (Tripping of maximum/minimum outlet pressure) do occur.

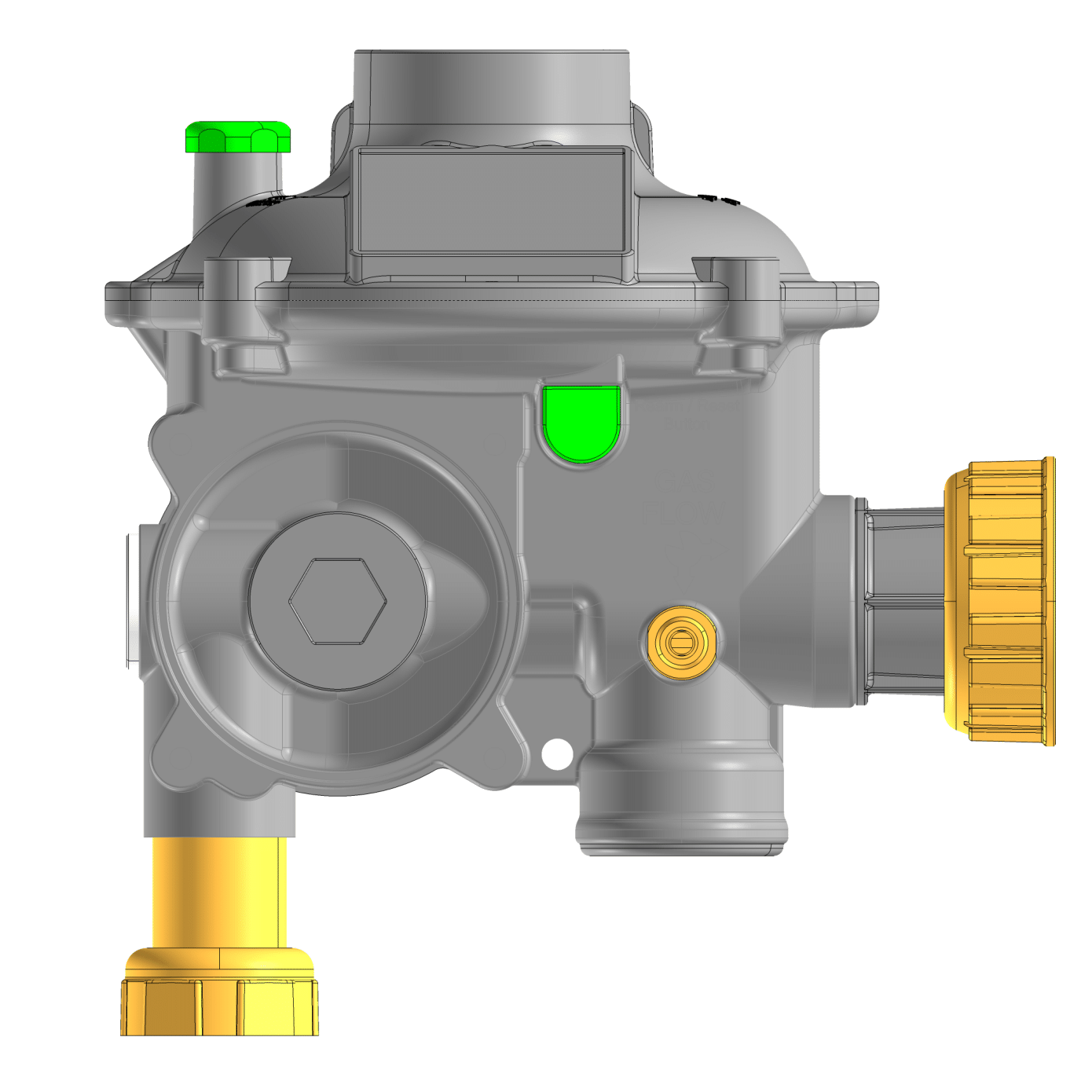

OPERATION

Making sure all the utility /apliance connections are closed securely, by opening regulator upstream valve sligtly and slowly, gas with inlet pressure initially flows through the inlet filter and comes in front of the first stage. Gently pull SSV re-arm knob to let the gas from SSV plug until conveying gas under 2 nd Stg Diaphragm and SSV Diaphragm where pressure is reduced to the desired outlet value. Downstream pressure must be be observed whether it is at desired values. After completing the procedure release push button and SSV re-arm knob observing SSV re-arm knob still stays pulled.